- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

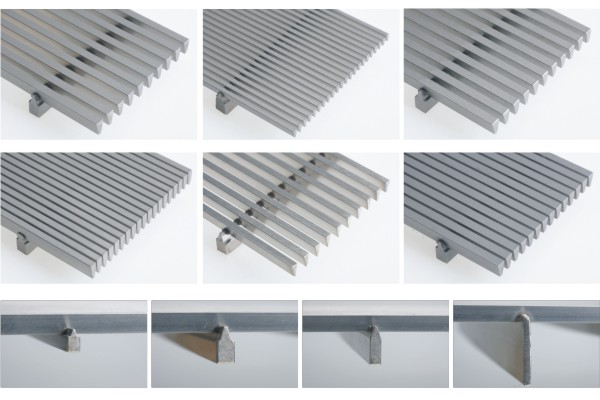

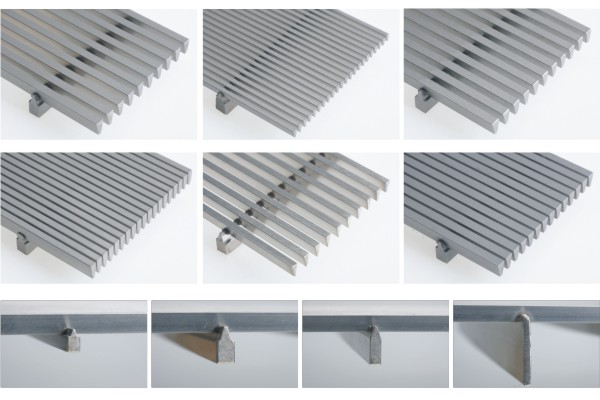

Anping County Xinlu Wire Mesh Products Co., Ltd. introduces the Flat Wedge Wire Screen Panel—a versatile, high-performance filtration solution designed to meet the diverse needs of global industries. Renowned for its precision, durability, and adaptability, this panel is a trusted choice for applications requiring accurate separation, dewatering, and sieving. Also known as Wire Wrapped Screen Panel, Johnson Screen Plate, V Wire Flat Panel, and Dewatering Screen Plate, the Flat Wedge Wire Screen Panel is crafted from a range of high-quality materials, including stainless steel, low carbon steel, and iron wire. Its continuous slot design and robust structure make it suitable for harsh environments, from water treatment plants to mining sites and food processing facilities. Whether you need a standard configuration or a custom solution, the Flat Wedge Wire Screen Panel delivers reliable performance across industries.

The Flat Wedge Wire Screen Panel offers unparalleled customization to suit specific industry requirements. From slot sizes (0.05mm to 3.00mm and beyond) to material selection and support rod types, every aspect is tailored to your application. This versatility makes it a go-to solution for industries as diverse as water treatment, mining, food processing, and oil & gas.

Constructed with robust materials—including stainless steel (SS-205, 304, 316), low carbon steel wire, and mild steel wire—the panel withstands corrosion, abrasion, and extreme temperatures. Its welded structure (wedge wire and support rods) ensures structural stability, even in high-pressure or high-volume operations. This durability translates to longer service life and lower maintenance costs.

The Flat Wedge Wire Screen Panel’s continuous slot design and precise slot sizes enable accurate filtration and separation of solids and liquids. Unlike traditional screens, its slots maintain consistency across the entire panel, preventing bypass and ensuring reliable results. This precision is critical for applications requiring high-purity outputs, such as food processing and water treatment.

Equipped with four types of support rods (V-shaped, wedge wire, square wire, and support bars), the panel offers exceptional structural integrity. Support rods are engineered to distribute pressure evenly, reducing the risk of warping or damage. This stability ensures consistent performance even in heavy-duty applications like mineral processing and coal cleaning.

The Flat Wedge Wire Screen Panel is designed with industry-specific performance in mind. Its material options balance cost and durability, while slot sizes and support rod types are optimized for different separation needs. Standard materials include stainless steel, carbon steel, and galvanized steel, with custom options available for unique project requirements. Each panel undergoes rigorous quality testing to meet global industry standards.

Parameter | Details |

Materials | Low Carbon Steel Wire, Iron Wire, Mild Steel Wire, Stainless Steel (SS-205, 304, 316) |

Slot Sizes | 0.05mm–3.00mm; Custom sizes available for specific needs |

Profile Wire Types | #63 (1.5×2.5mm), #93 (2.3×3.5mm), #118 (3.0×4.6mm), etc. |

Support Rod Types | V-shaped, Wedge Wire, Square Wire, Support Bar (various dimensions) |

Standard Materials | Stainless steel, carbon steel, galvanized steel |

Custom Options | Available for material, size, and structure |

The Flat Wedge Wire Screen Panel is used in municipal water treatment plants, wastewater treatment facilities, and water wells. Its corrosion resistance and precise slot sizes make it ideal for filtering sediment, debris, and contaminants, ensuring clean water output.

In food processing, the panel meets hygiene standards (food-grade materials) and is used for sieving, dewatering, and separating food particles. Applications include grain processing, fruit juice filtration, and dairy production.

The panel’s durability and abrasion resistance make it suitable for mineral processing, coal cleaning plants, and aggregate processing. It efficiently separates ore particles, coal, and aggregates, supporting high-volume operations.

In the oil & gas industry, the Flat Wedge Wire Screen Panel is used as well screens, filtering sand and sediment from oil and gas wells. Its corrosion resistance and structural stability ensure reliable performance in downhole environments.

Anping County Xinlu Wire Mesh Products Co., Ltd. adheres to strict quality control processes to ensure the Flat Wedge Wire Screen Panel meets international industry standards. Each panel is rigorously tested for slot precision, structural integrity, and material quality before delivery. We prioritize secure packaging and on-time transportation, ensuring products arrive intact and ready for use. Our brand is committed to delivering versatile, high-quality filtration solutions—we collaborate with clients to understand their unique challenges and provide custom Flat Wedge Wire Screen Panel configurations that drive efficiency and productivity. With a focus on innovation and customer satisfaction, we strive to exceed industry expectations and build long-term trust with partners worldwide.

Anping County Xinlu Wire Mesh Products Co., Ltd. introduces the Flat Wedge Wire Screen Panel—a versatile, high-performance filtration solution designed to meet the diverse needs of global industries. Renowned for its precision, durability, and adaptability, this panel is a trusted choice for applications requiring accurate separation, dewatering, and sieving. Also known as Wire Wrapped Screen Panel, Johnson Screen Plate, V Wire Flat Panel, and Dewatering Screen Plate, the Flat Wedge Wire Screen Panel is crafted from a range of high-quality materials, including stainless steel, low carbon steel, and iron wire. Its continuous slot design and robust structure make it suitable for harsh environments, from water treatment plants to mining sites and food processing facilities. Whether you need a standard configuration or a custom solution, the Flat Wedge Wire Screen Panel delivers reliable performance across industries.

The Flat Wedge Wire Screen Panel offers unparalleled customization to suit specific industry requirements. From slot sizes (0.05mm to 3.00mm and beyond) to material selection and support rod types, every aspect is tailored to your application. This versatility makes it a go-to solution for industries as diverse as water treatment, mining, food processing, and oil & gas.

Constructed with robust materials—including stainless steel (SS-205, 304, 316), low carbon steel wire, and mild steel wire—the panel withstands corrosion, abrasion, and extreme temperatures. Its welded structure (wedge wire and support rods) ensures structural stability, even in high-pressure or high-volume operations. This durability translates to longer service life and lower maintenance costs.

The Flat Wedge Wire Screen Panel’s continuous slot design and precise slot sizes enable accurate filtration and separation of solids and liquids. Unlike traditional screens, its slots maintain consistency across the entire panel, preventing bypass and ensuring reliable results. This precision is critical for applications requiring high-purity outputs, such as food processing and water treatment.

Equipped with four types of support rods (V-shaped, wedge wire, square wire, and support bars), the panel offers exceptional structural integrity. Support rods are engineered to distribute pressure evenly, reducing the risk of warping or damage. This stability ensures consistent performance even in heavy-duty applications like mineral processing and coal cleaning.

The Flat Wedge Wire Screen Panel is designed with industry-specific performance in mind. Its material options balance cost and durability, while slot sizes and support rod types are optimized for different separation needs. Standard materials include stainless steel, carbon steel, and galvanized steel, with custom options available for unique project requirements. Each panel undergoes rigorous quality testing to meet global industry standards.

Parameter | Details |

Materials | Low Carbon Steel Wire, Iron Wire, Mild Steel Wire, Stainless Steel (SS-205, 304, 316) |

Slot Sizes | 0.05mm–3.00mm; Custom sizes available for specific needs |

Profile Wire Types | #63 (1.5×2.5mm), #93 (2.3×3.5mm), #118 (3.0×4.6mm), etc. |

Support Rod Types | V-shaped, Wedge Wire, Square Wire, Support Bar (various dimensions) |

Standard Materials | Stainless steel, carbon steel, galvanized steel |

Custom Options | Available for material, size, and structure |

The Flat Wedge Wire Screen Panel is used in municipal water treatment plants, wastewater treatment facilities, and water wells. Its corrosion resistance and precise slot sizes make it ideal for filtering sediment, debris, and contaminants, ensuring clean water output.

In food processing, the panel meets hygiene standards (food-grade materials) and is used for sieving, dewatering, and separating food particles. Applications include grain processing, fruit juice filtration, and dairy production.

The panel’s durability and abrasion resistance make it suitable for mineral processing, coal cleaning plants, and aggregate processing. It efficiently separates ore particles, coal, and aggregates, supporting high-volume operations.

In the oil & gas industry, the Flat Wedge Wire Screen Panel is used as well screens, filtering sand and sediment from oil and gas wells. Its corrosion resistance and structural stability ensure reliable performance in downhole environments.

Anping County Xinlu Wire Mesh Products Co., Ltd. adheres to strict quality control processes to ensure the Flat Wedge Wire Screen Panel meets international industry standards. Each panel is rigorously tested for slot precision, structural integrity, and material quality before delivery. We prioritize secure packaging and on-time transportation, ensuring products arrive intact and ready for use. Our brand is committed to delivering versatile, high-quality filtration solutions—we collaborate with clients to understand their unique challenges and provide custom Flat Wedge Wire Screen Panel configurations that drive efficiency and productivity. With a focus on innovation and customer satisfaction, we strive to exceed industry expectations and build long-term trust with partners worldwide.