- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

3-1/2", 7", 9-5/8", 13-3/8"

Xinlu

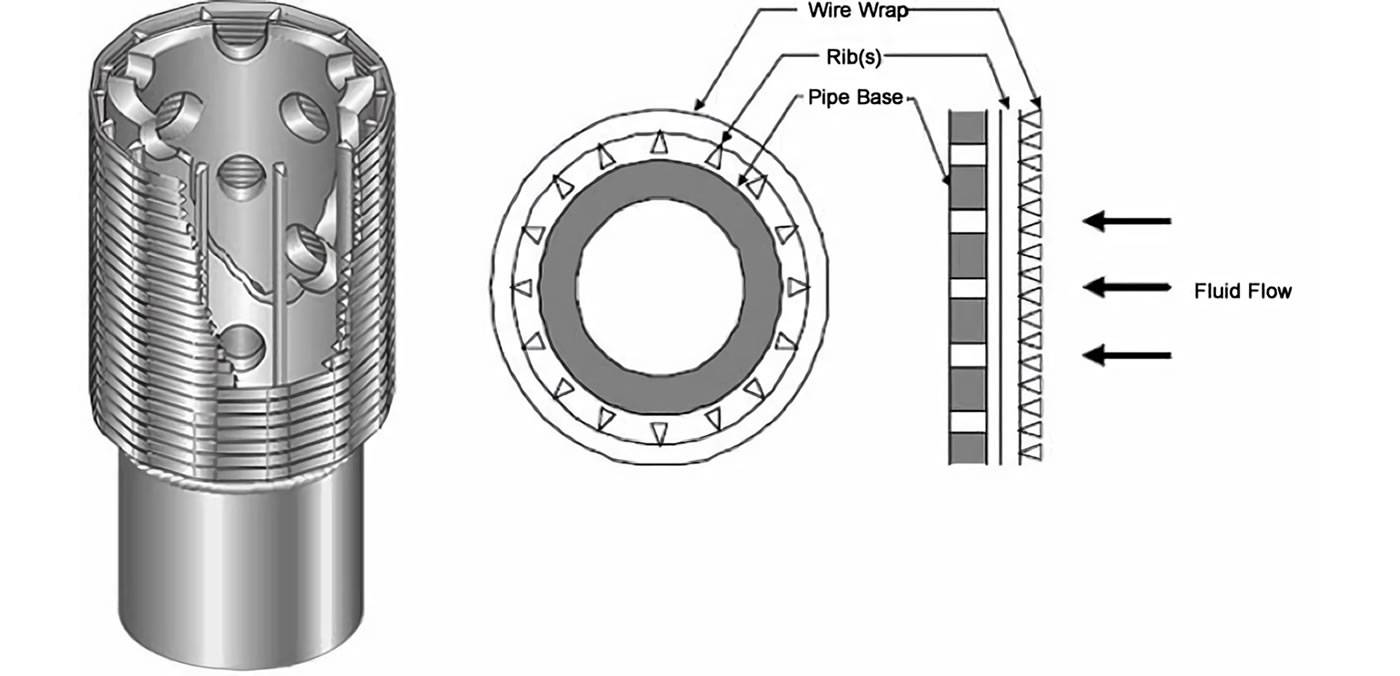

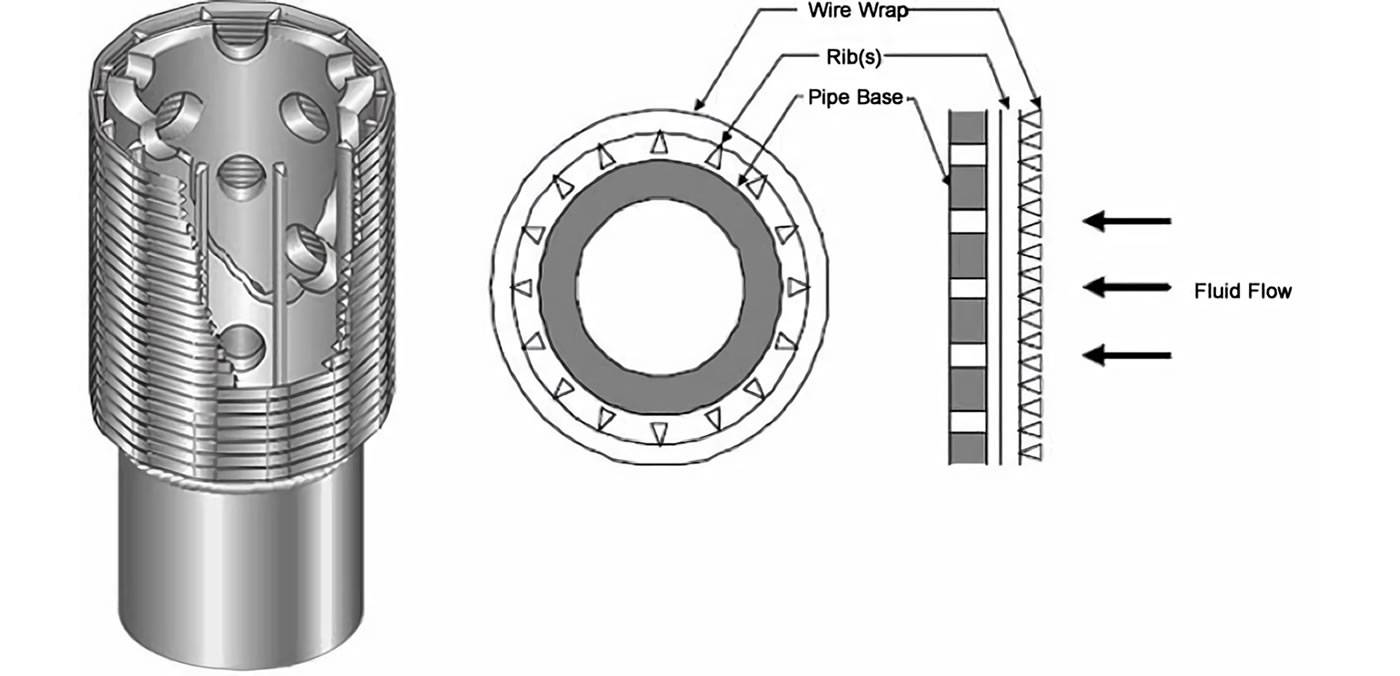

Anping County Xinlu Wire Mesh Products Co., Ltd. specializes in manufacturing premium Pipe Based Oil Well Screen, a precision-engineered solution designed to address sand control challenges in high-pressure and high-temperature downhole environments. Our screens integrate high-precision wedge wire with an API-compliant base pipe, delivering exceptional structural integrity and long-term performance for oil, gas, and geothermal well operations. As a core product under the water well screen category, Oil Well Screen effectively prevents sand plugging, reduces pressure drop, and boosts fluid flow rate, making it a trusted choice for oilfield operators worldwide.

Beyond the flagship Pipe Based Oil Well Screen, Xinlu offers a comprehensive product line to meet diverse well requirements, including Wire-Wrapped Screens, Bridge Slotted Screens, and Continuous Slot Screens. All products are tailored to fit different well sizes and operating conditions, with customizable options available to match specific project demands.

Our Pipe Based Oil Well Screen features a high-precision manufacturing process, making it suitable for extreme downhole scenarios such as deviated wells. The all-welded structure ensures superior mechanical strength, enabling the screen to withstand harsh pressure and temperature fluctuations without deformation. This precision design minimizes gaps between wedge wires, ensuring accurate particle size control for optimal sand control effects.

A key differentiator of our Oil Well Screen is its unique double-layer structure, combining a sturdy base pipe with an outer wedge wire screen layer for enhanced support. By adopting smaller wedge wire diameters, we achieve a larger open flow area without compromising structural strength. This design reduces fluid resistance, increases production flow rate, and lowers operational costs for oilfield projects.

The Pipe Based Oil Well Screen is equipped with a built-in self-cleaning function, which significantly reduces the risk of plugging caused by sand accumulation. This feature extends the screen’s service life and reduces maintenance frequency. Additionally, we offer versatile connection methods, including threaded, flange, and welding connections, to accommodate different well completion designs and installation requirements.

To meet precise oilfield operational needs, our Oil Well Screen offers customizable technical specifications, with core parameters as follows:

Materials: Stainless steel grades 304, 304L, 316, 316L, galvanized low-carbon steel, or custom materials upon request, ensuring excellent corrosion and erosion resistance.

Slot Openings: 0.1mm to 15mm, tailored to specific well sand particle sizes for targeted sand control.

Dimensions: Diameters range from 2 inches (50mm) to 20 inches (500mm), with standard lengths of 2.9m and 5.85m, and a maximum customizable length of 6.05m. Wall thickness is optimized at 3.5mm to 8mm for balanced strength and weight.

Base Pipe Compliance: The base pipe is made of API-compliant materials such as J55, K55, N80, and stainless steel 304, ensuring compatibility with industry standards.

Our Pipe Based Oil Well Screen is ideal for various well types, including vertical wells, horizontal multi-lateral wells, and high load-bearing wells. Its robust structure ensures stable performance even in complex well trajectories, making it a versatile solution for different oilfield development projects.

The screen excels in high-pressure and high-temperature downhole environments, supporting gravel packing and open-hole completions. It is widely applied in sand control operations for oil wells, gas wells, and geothermal wells, effectively protecting well equipment and improving production efficiency.

Xinlu’s Oil Well Screen is manufactured in strict accordance with API standards, integrating advanced production technology and decades of industry experience. We implement rigorous quality control processes throughout the manufacturing cycle, from raw material selection to finished product testing, ensuring every screen exceeds industry performance benchmarks. Our commitment to quality has earned us recognition from oilfield clients globally, establishing Xinlu as a reliable manufacturer of industrial wire mesh products.

If you are seeking a high-performance Oil Well Screen for your sand control project, contact Xinlu today. Our professional engineering team is ready to provide customized solutions, detailed product catalogs, and competitive quotes.

Inquire Now: Reach us via WhatsApp at +8613315867171 or email at starlee@feiyaguoji.com for personalized support.

Customization Service: Share your well drawings and operational requirements to get a tailored Pipe Based Oil Well Screen solution.

Anping County Xinlu Wire Mesh Products Co., Ltd. specializes in manufacturing premium Pipe Based Oil Well Screen, a precision-engineered solution designed to address sand control challenges in high-pressure and high-temperature downhole environments. Our screens integrate high-precision wedge wire with an API-compliant base pipe, delivering exceptional structural integrity and long-term performance for oil, gas, and geothermal well operations. As a core product under the water well screen category, Oil Well Screen effectively prevents sand plugging, reduces pressure drop, and boosts fluid flow rate, making it a trusted choice for oilfield operators worldwide.

Beyond the flagship Pipe Based Oil Well Screen, Xinlu offers a comprehensive product line to meet diverse well requirements, including Wire-Wrapped Screens, Bridge Slotted Screens, and Continuous Slot Screens. All products are tailored to fit different well sizes and operating conditions, with customizable options available to match specific project demands.

Our Pipe Based Oil Well Screen features a high-precision manufacturing process, making it suitable for extreme downhole scenarios such as deviated wells. The all-welded structure ensures superior mechanical strength, enabling the screen to withstand harsh pressure and temperature fluctuations without deformation. This precision design minimizes gaps between wedge wires, ensuring accurate particle size control for optimal sand control effects.

A key differentiator of our Oil Well Screen is its unique double-layer structure, combining a sturdy base pipe with an outer wedge wire screen layer for enhanced support. By adopting smaller wedge wire diameters, we achieve a larger open flow area without compromising structural strength. This design reduces fluid resistance, increases production flow rate, and lowers operational costs for oilfield projects.

The Pipe Based Oil Well Screen is equipped with a built-in self-cleaning function, which significantly reduces the risk of plugging caused by sand accumulation. This feature extends the screen’s service life and reduces maintenance frequency. Additionally, we offer versatile connection methods, including threaded, flange, and welding connections, to accommodate different well completion designs and installation requirements.

To meet precise oilfield operational needs, our Oil Well Screen offers customizable technical specifications, with core parameters as follows:

Materials: Stainless steel grades 304, 304L, 316, 316L, galvanized low-carbon steel, or custom materials upon request, ensuring excellent corrosion and erosion resistance.

Slot Openings: 0.1mm to 15mm, tailored to specific well sand particle sizes for targeted sand control.

Dimensions: Diameters range from 2 inches (50mm) to 20 inches (500mm), with standard lengths of 2.9m and 5.85m, and a maximum customizable length of 6.05m. Wall thickness is optimized at 3.5mm to 8mm for balanced strength and weight.

Base Pipe Compliance: The base pipe is made of API-compliant materials such as J55, K55, N80, and stainless steel 304, ensuring compatibility with industry standards.

Our Pipe Based Oil Well Screen is ideal for various well types, including vertical wells, horizontal multi-lateral wells, and high load-bearing wells. Its robust structure ensures stable performance even in complex well trajectories, making it a versatile solution for different oilfield development projects.

The screen excels in high-pressure and high-temperature downhole environments, supporting gravel packing and open-hole completions. It is widely applied in sand control operations for oil wells, gas wells, and geothermal wells, effectively protecting well equipment and improving production efficiency.

Xinlu’s Oil Well Screen is manufactured in strict accordance with API standards, integrating advanced production technology and decades of industry experience. We implement rigorous quality control processes throughout the manufacturing cycle, from raw material selection to finished product testing, ensuring every screen exceeds industry performance benchmarks. Our commitment to quality has earned us recognition from oilfield clients globally, establishing Xinlu as a reliable manufacturer of industrial wire mesh products.

If you are seeking a high-performance Oil Well Screen for your sand control project, contact Xinlu today. Our professional engineering team is ready to provide customized solutions, detailed product catalogs, and competitive quotes.

Inquire Now: Reach us via WhatsApp at +8613315867171 or email at starlee@feiyaguoji.com for personalized support.

Customization Service: Share your well drawings and operational requirements to get a tailored Pipe Based Oil Well Screen solution.

All listed parameters are for reference only. Xinlu provides customized specification services, adjusting slot openings, dimensions, and materials according to clients’ well drawings and operational requirements.

Base Pipe | Screen Jacket | |||||||||

Nominal Diameter (in) | Outside Diameter (mm) | Weight lb/ft Wall Thickness (mm) | Hole diameter in | Hole Density | Hole Aprea In2/ft | OD of Screen Jacket (in) | Open area In2/ft Slot | |||

0.008” | 0.012” | 0.015” | 0.020” | |||||||

2-3/8 | 60.3 | 4.6(4.83) | 3/8 | 96 | 10.60 | 2.86 | 12.68 | 17.96 | 21.56 | 26.95 |

2-7/8 | 73 | 6.4(5.51) | 3/8 | 108 | 11.93 | 3.38 | 14.99 | 21.23 | 25.48 | 31.85 |

3-1/2 | 88.9 | 9.2(6.45) | 1/2 | 108 | 21.21 | 4.06 | 18.00 | 25.50 | 30.61 | 38.26 |

4 | 101.6 | 9.5(5.74) | 1/2 | 120 | 23.56 | 4.55 | 20.18 | 28.58 | 34.30 | 42.88 |

4-1/2 | 114.3 | 11.6(6.35) | 1/2 | 144 | 28.27 | 5.08 | 15.63 | 22.53 | 27.35 | 34.82 |

5 | 127 | 13(6.43) | 1/2 | 156 | 30.63 | 5.62 | 17.29 | 24.92 | 30.26 | 38.52 |

5-1/2 | 139.7 | 15.5(6.99) | 1/2 | 168 | 32.99 | 6.08 | 18.71 | 26.96 | 32.74 | 41.67 |

6-5/8 | 168.3 | 24(8.94) | 1/2 | 180 | 35.34 | 7.12 | 21.91 | 31.57 | 38.34 | 48.80 |

7 | 177.8 | 23(8.05) | 5/8 | 136 | 42.16 | 7.58 | 23.32 | 33.61 | 40.82 | 51.95 |

7-5/8 | 194 | 26.4(8.33) | 5/8 | 148 | 45.88 | 8.20 | 25.23 | 36.36 | 44.16 | 56.20 |

8-5/8 | 219 | 32(8.94) | 5/8 | 168 | 51.08 | 9.24 | 28.43 | 40.98 | 49.76 | 63.33 |

9-5/8 | 244.5 | 36(8.94) | 5/8 | 188 | 58.28 | 10.18 | 31.32 | 45.15 | 54.82 | 69.77 |

10-3/4 | 273 | 45.5(10.16) | 5/8 | 209 | 64.79 | 11.36 | 34.95 | 50.38 | 61.18 | 77.86 |

13-3/8 | 339.7 | 54.5(9.65) | 5/8 | 260 | 80.60 | 14.04 | 37.80 | 54.93 | 66.87 | 85.17 |

All listed parameters are for reference only. Xinlu provides customized specification services, adjusting slot openings, dimensions, and materials according to clients’ well drawings and operational requirements.

Base Pipe | Screen Jacket | |||||||||

Nominal Diameter (in) | Outside Diameter (mm) | Weight lb/ft Wall Thickness (mm) | Hole diameter in | Hole Density | Hole Aprea In2/ft | OD of Screen Jacket (in) | Open area In2/ft Slot | |||

0.008” | 0.012” | 0.015” | 0.020” | |||||||

2-3/8 | 60.3 | 4.6(4.83) | 3/8 | 96 | 10.60 | 2.86 | 12.68 | 17.96 | 21.56 | 26.95 |

2-7/8 | 73 | 6.4(5.51) | 3/8 | 108 | 11.93 | 3.38 | 14.99 | 21.23 | 25.48 | 31.85 |

3-1/2 | 88.9 | 9.2(6.45) | 1/2 | 108 | 21.21 | 4.06 | 18.00 | 25.50 | 30.61 | 38.26 |

4 | 101.6 | 9.5(5.74) | 1/2 | 120 | 23.56 | 4.55 | 20.18 | 28.58 | 34.30 | 42.88 |

4-1/2 | 114.3 | 11.6(6.35) | 1/2 | 144 | 28.27 | 5.08 | 15.63 | 22.53 | 27.35 | 34.82 |

5 | 127 | 13(6.43) | 1/2 | 156 | 30.63 | 5.62 | 17.29 | 24.92 | 30.26 | 38.52 |

5-1/2 | 139.7 | 15.5(6.99) | 1/2 | 168 | 32.99 | 6.08 | 18.71 | 26.96 | 32.74 | 41.67 |

6-5/8 | 168.3 | 24(8.94) | 1/2 | 180 | 35.34 | 7.12 | 21.91 | 31.57 | 38.34 | 48.80 |

7 | 177.8 | 23(8.05) | 5/8 | 136 | 42.16 | 7.58 | 23.32 | 33.61 | 40.82 | 51.95 |

7-5/8 | 194 | 26.4(8.33) | 5/8 | 148 | 45.88 | 8.20 | 25.23 | 36.36 | 44.16 | 56.20 |

8-5/8 | 219 | 32(8.94) | 5/8 | 168 | 51.08 | 9.24 | 28.43 | 40.98 | 49.76 | 63.33 |

9-5/8 | 244.5 | 36(8.94) | 5/8 | 188 | 58.28 | 10.18 | 31.32 | 45.15 | 54.82 | 69.77 |

10-3/4 | 273 | 45.5(10.16) | 5/8 | 209 | 64.79 | 11.36 | 34.95 | 50.38 | 61.18 | 77.86 |

13-3/8 | 339.7 | 54.5(9.65) | 5/8 | 260 | 80.60 | 14.04 | 37.80 | 54.93 | 66.87 | 85.17 |